Service Hotline

0575-83106186

SFJ thermoplastic micro powder grinder is independently developed by our factory, which can crush thermoplastic materials (such as polyethylene, polyvinyl chloride, polypropylene, PVE, PBT, EVA nylon) at room temperature. Compared with low-temperature cooling crushing equipment, this device has the advantages of low energy consumption, uniform product particle size, and easy operation. It is currently an ideal equipment for processing plastic powder at room temperature. This equipment adopts a combination of grinding disc water cooling and air cooling, with dual cooling function, and can complete continuous crushing processing at room temperature. The product fineness can reach below 150 mesh, and the output can reach 50-200 kilograms per hour.

SFJ thermoplastic micro powder grinder is independently developed by our factory, which can crush thermoplastic materials (such as polyethylene, polyvinyl chloride, polypropylene, PVE, PBT, EVA nylon) at room temperature. Compared with low-temperature cooling crushing equipment, this device has the advantages of low energy consumption, uniform product particle size, and easy operation. It is currently an ideal equipment for processing plastic powder at room temperature. This equipment adopts a combination of grinding disc water cooling and air cooling, with dual cooling function, and can complete continuous crushing processing at room temperature. The product fineness can reach below 150 mesh, and the output can reach 50-200 kilograms per hour.

SFJ thermoplastic micro powder grinder is independently developed by our factory, which can crush thermoplastic materials (such as polyethylene, polyvinyl chloride, polypropylene, PVE, PBT, EVA nylon) at room temperature. Compared with low-temperature cooling crushing equipment, this device has the advantages of low energy consumption, uniform product particle size, and easy operation. It is currently an ideal equipment for processing plastic powder at room temperature. This equipment adopts a combination of grinding disc water cooling and air cooling, with dual cooling function, and can complete continuous crushing processing at room temperature. The product fineness can reach below 150 mesh, and the output can reach 50-200 kilograms per hour.

WCM series horizontal ultrafine impact mill: This micro grinder is suitable for ultrafine grinding in industries such as chemical, food, feed, pharmaceutical and intermediate, tobacco, pesticide (wettable powder), pigment, coating, dye, ceramic, colorant, colloid, non-metallic mineral and biotechnology (such as calcium carbonate, magnesium oxide, aluminum hydroxide, cerium oxide, phenolic resin, alpha starch, pentasodium, mica, etc.)

WCM series horizontal ultrafine impact mill: This micro grinder is suitable for ultrafine grinding in industries such as chemical, food, feed, pharmaceutical and intermediate, tobacco, pesticide (wettable powder), pigment, coating, dye, ceramic, colorant, colloid, non-metallic mineral and biotechnology (such as calcium carbonate, magnesium oxide, aluminum hydroxide, cerium oxide, phenolic resin, alpha starch, pentasodium, mica, etc.)

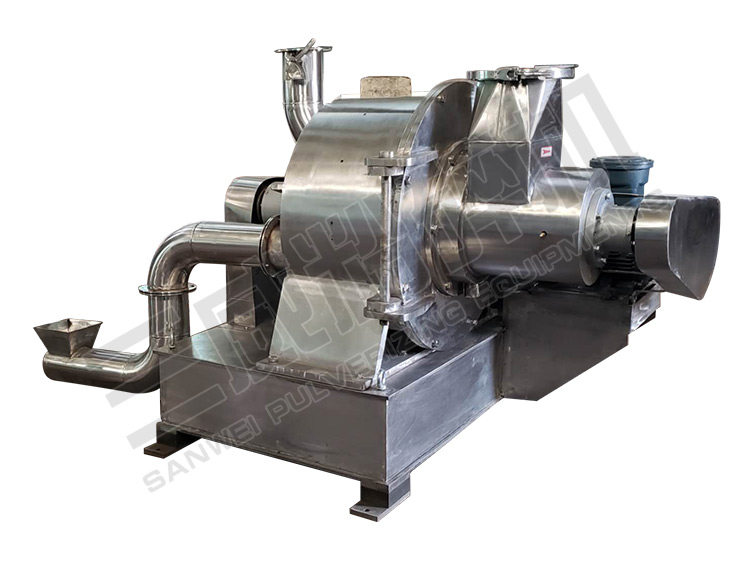

WDJ turbine pulverizer is a pulverizer equipment suitable for ultra large micro pulverization of various materials. This machine has a unique crushing mechanism, ultrasonic crushing and high-frequency micro vibration crushing functions, with dual functions of drying and crushing simultaneously. Its advantages are high output, fine crushing particle size, and adjustable particle size without stopping the machine. Widely applicable to industries such as chemical, pharmaceutical, dye, feed, non-metallic minerals, etc., and capable of processing materials with high thermal sensitivity, toughness, fiber and moisture content that are difficult to crush with general micro crushers.

WDJ turbine pulverizer is a pulverizer equipment suitable for ultra large micro pulverization of various materials. This machine has a unique crushing mechanism, ultrasonic crushing and high-frequency micro vibration crushing functions, with dual functions of drying and crushing simultaneously. Its advantages are high output, fine crushing particle size, and adjustable particle size without stopping the machine. Widely applicable to industries such as chemical, pharmaceutical, dye, feed, non-metallic minerals, etc., and capable of processing materials with high thermal sensitivity, toughness, fiber and moisture content that are difficult to crush with general micro crushers.

Our company has independently developed it. The rubber micro crushing production equipment with advanced level in the 1990s solves the problem of difficult crushing of rubber at room temperature. It is currently an ideal equipment for processing rubber powder at room temperature, widely used for micro powder processing of rubber products such as waste tires and shoe soles. The structural principle is achieved through precise coordination between the rotor and stator, forming a shearing and grinding effect to achieve the crushing effect of the material. Adjusting the gap between the rotor and stator can result in products of different fineness. The rotor and stator of the machine are made of YG8 hard alloy, which makes the rotor and stator durable. The stator also has a water cooling function, which enables the equipment to work continuously for a long time, ensuring product quality and performance.

Our company has independently developed it. The rubber micro crushing production equipment with advanced level in the 1990s solves the problem of difficult crushing of rubber at room temperature. It is currently an ideal equipment for processing rubber powder at room temperature, widely used for micro powder processing of rubber products such as waste tires and shoe soles. The structural principle is achieved through precise coordination between the rotor and stator, forming a shearing and grinding effect to achieve the crushing effect of the material. Adjusting the gap between the rotor and stator can result in products of different fineness. The rotor and stator of the machine are made of YG8 hard alloy, which makes the rotor and stator durable. The stator also has a water cooling function, which enables the equipment to work continuously for a long time, ensuring product quality and performance.

The CWFJ series ultrafine air classifier is an ultrafine grading equipment introduced by our company with advanced foreign technology, suitable for grading low to medium hardness ultrafine powder materials. Its performance indicators have reached international standards for similar models. In 2004, the product passed the provincial new product appraisal and won the Zhejiang Province and Shaoxing City Science and Technology Progress Award. And it has been listed as a national torch plan project. This machine is equipped with secondary air intake and high-precision turbine, which can obtain fine materials as fine as 3 microns. The rotor made of special materials can grade high hardness materials, and is widely used in industries such as chemical, pharmaceutical, food, non-metallic minerals, etc. for particle separation, iron removal, and selection in ultrafine powder processing.

The CWFJ series ultrafine air classifier is an ultrafine grading equipment introduced by our company with advanced foreign technology, suitable for grading low to medium hardness ultrafine powder materials. Its performance indicators have reached international standards for similar models. In 2004, the product passed the provincial new product appraisal and won the Zhejiang Province and Shaoxing City Science and Technology Progress Award. And it has been listed as a national torch plan project. This machine is equipped with secondary air intake and high-precision turbine, which can obtain fine materials as fine as 3 microns. The rotor made of special materials can grade high hardness materials, and is widely used in industries such as chemical, pharmaceutical, food, non-metallic minerals, etc. for particle separation, iron removal, and selection in ultrafine powder processing.

The HTC series high-efficiency turbo ultrafine classifier is an ultrafine grading device suitable for grading low to medium hardness ultrafine powder materials, with all performance indicators meeting the standards. This machine is equipped with secondary air intake and high-precision turbine, which can obtain fine materials with a fineness of up to 3 microns. The rotor made of special materials can be graded, and high hardness materials are widely used in the processing of ultrafine powders in industries such as chemistry, medicine, food, and non-metallic minerals for particle separation, iron removal, and selection.